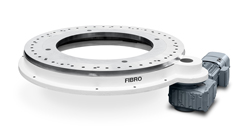

Especially for car body assembly applications in the automobile industry, rotary table specialist FIBRO of Weinsberg has developed a modular heavy-load positioning table that positions large and heavy parts or equipment quickly and precisely. As the very first supplier, FIBRO implements a consistently modular and thus price/performance-optimised concept for a positioning table of this size. The maintenance-free FIBROMAT, which is lubricated for life, is driven by spur gear toothing and equipped with pneumatic indexing upon request. In contrast to conventional positioning tables with a cylinder cam, the gearbox of the FIBROMAT is not self-inhibiting so that the force is not transferred to the cam in case of a sudden power failure or emergency stop. Damage to the mechanical system of the rotary table is thus not possible. In addition, the table does not swing open during positioning, even with superstructures on the table top.

Short stopping times

Due to the modular concept, users and designers have an absolutely free hand in the selection of the motor. Without a motor, the rotary table can be driven by hand or by robot. When equipped with a drive, the positioning table covers about 80 percent of all possible applications. With two parallel drives, shorter switching times can be realised or the control response of large loads can be optimised. The number of motors also affects the emergency stop times. At a table top speed of 8 rpm and moment of inertia of 16,000 kgm² with one drive, 1.6 s pass until standstill occurs; with two drives, the stopping time is lowered to an extremely short 0.8 s. The drives are placed in such a way that they can be removed downwards with minimum effort and without dismantling the connection structure.

In the basic version, the rotary table is equipped with an asynchronous servo - gear motor with a preconfigured drive converter. All other common motor types of the known manufacturers can be used just as well. FIBROMAT can thus be synchronised as an additional axis on a robot using synchronous servo motors and actuated using the same set of commands as for the robot. In the standard version, the positioning table has a large, centre borehole especially for robotsupported applications.

The bearing of the rotary table also has a modular design. Instead of the standard roller bearing of the basic version, a rigidity-optimised cross roller bearing is used that can take up particularly high tilting moments in the axial and radial direction. Upon desire, the FIBROMAT is available with indexing units up to Division 20. The indexing accuracy then lies at +/- 20 angle seconds and the repeat accuracy at 10 angle seconds. Alternatively, any position can be freely taught and tensioned using the motor brake without play by software with a master-slave drive.

Extremely flat

The extensive module programme of FIBROMAT comprises media distributors, collector ring transfers, and absolute measuring systems. The torque can be increased using an additional drive. Since the FIBROMAT has an extremely flat construction, it can be either sunk into the floor or placed at an ergonomical height using a machine stand. Special connecting dimensions and customerspecific drilling templates can be implemented quickly and affordably. To protect against welding beads, FIBRO has also covered all seals. In the standard version, the heavy-load positioning table is available in four sizes, with table top diameters of 800 mm, 1,000 mm, 1,250 mm, and 1,600 mm. At size 1,000, superstructures up to a diameter of 6,000 mm and transport loads up to 12 t are possible. The consistent modular design guarantees short delivery times.

|